Structure Monitoring

Structure deformation and impacts detection on various structures and materials, crucial for industries where reliability, accuracy, and safety are paramount.

Concept

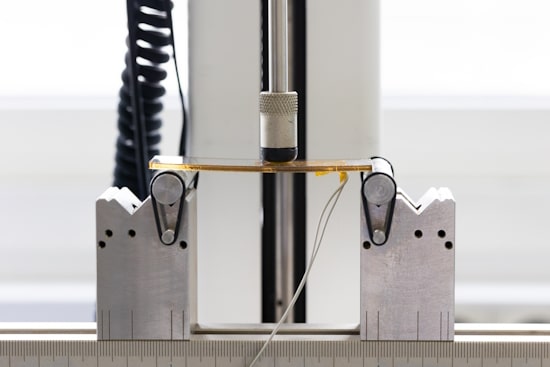

Nanomade deformation sensors are designed to discern even the minutest deformations and impacts across a diverse array of structures and materials, ranging from resilient metals to advanced carbon fibers.

Deployed across critical sectors such as aerospace, automotive, and construction, these sensors play a pivotal role in ensuring the reliability, precision, and safety of intricate systems and structures.

With their high-sensitivity and robustness, our sensors enables engineers and stakeholders to proactively monitor and mitigate potential risks, thereby elevating operational efficiency and safeguarding against structural integrity compromises in high-stakes environments.

Deformation

Impact

Advanced monitoring

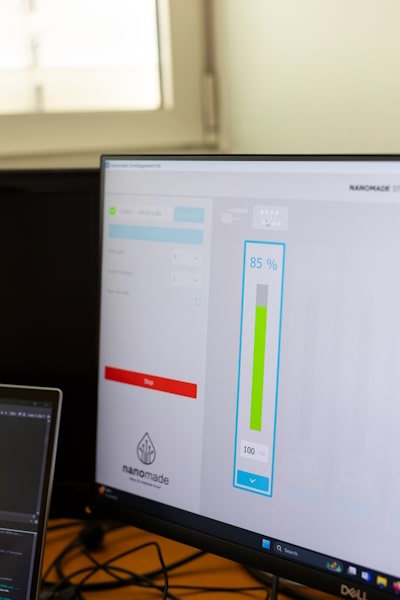

Nanomade’s Structure Deformation application represents a significant advancement in monitoring the integrity and safety of various structures. By detecting even minute changes in shape, our sensors provide real-time insights into deformation within materials and systems.

This capability is critical for industries such as aerospace, automotive, and civil engineering, where maintaining structural integrity is essential. With our technology, stress points and potential failures can be identified early, allowing for timely preventive action and reducing the risk of catastrophic outcomes.

Integration and flexibility

One of the standout features of our Structure Deformation application is its ease of integration. Designed for adaptability, our sensors can be installed on existing infrastructure without requiring major alterations, making them ideal for retrofitting projects.

Nanomade sensors are also built to withstand environmental extremes, including temperature fluctuations and humidity, ensuring consistent performance under challenging conditions.

Our innovative design capabilities further extend monitoring possibilities. With flex lengths reaching up to 10 meters, our sensors can gather data from remote or previously inaccessible areas, such as the tip of an aircraft wing, without requiring nearby electronic components. This reduces weight while enabling comprehensive structural monitoring in locations where traditional sensors fall short.

Additionally, each sensor can support up to 250 active sensing zones within an area the size of an A5 sheet of paper. This high-density integration eliminates the need for multiple sensors across a surface, simplifying installation and reducing the overall weight of electronics. These advancements make our solution lighter, more efficient, and more precise across multiple critical points.

Water-proof

Dust-proof

5kΩ resistance

180 gauge factor

Showreel Structure Monitoring

Applications across industries

By integrating Nanomade sensors into structures such as vehicle components, aircraft parts, or building infrastructure, organizations can monitor deformation data in real-time, ensuring structural integrity and safety.

For example, in aerospace, our sensors can track the stress on airplane wings to detect potential wear before it becomes hazardous. In construction, they can monitor skyscrapers for structural shifts due to weather or aging, providing valuable data to guide maintenance. Automotive applications benefit similarly, ensuring the durability and performance of critical vehicle components under dynamic conditions.

With their precision and durability, Nanomade sensors empower engineers to enhance safety, optimize performance, and extend the lifespan of infrastructure in diverse industries.

Safer and resilient infrastructure

Nanomade’s Structure Deformation solution offers a reliable, cost-effective approach to monitoring and maintaining structural integrity. Whether applied to airplane wings, skyscrapers, or factory assembly lines, our sensors provide the precision and robustness necessary for high-stakes applications.

By delivering real-time data on structural health, we empower engineers to make informed decisions, prevent failures, and improve the resilience of critical infrastructure. With Nanomade, organisations can innovate confidently, knowing their assets are safeguarded by the best in sensor technology.