Project

Nanomade set out to provide retailers with a real-time, centralised and efficient stock management solution. Our ambition was to offer a highly advanced, yet cost-effective technology, ideal for large areas such as warehouses.

Implementation

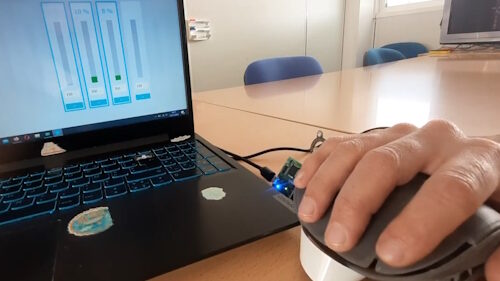

Our Smart Shelf is a prototype of a multi-point force sensing system that accurately locates objects on a shelf. Our current version is already capable of determining whether an object has been :

- removed ;

- moved ;

- replaced.

Eventually, the Smart Shelf will offer the ability to provide detailed information such as the type, location, shape and quantity of objects on the shelf. Incorporating artificial intelligence processes, all shelf data in a warehouse will be centralised on your computer, enabling sales and stock management data to be updated in real time.

The Nanomade solution

Our Smart Shelf sensor, based on an exclusive ink, transforms the surface on which it is printed into a sensitive, multi-force platform. With a thickness of just 0.5mm, natural flexibility and extensive compatibility with a variety of materials, this force interface technology offers exceptional adaptability, whether used on small or large surfaces.

This Nanomade innovation revolutionises stock management for retailers, offering an advanced and accurate solution, propelling warehouse management into a new era of control and efficiency.

Client

Retail, Supply chain…

Release Date

2021/08/16